List of developments and albums

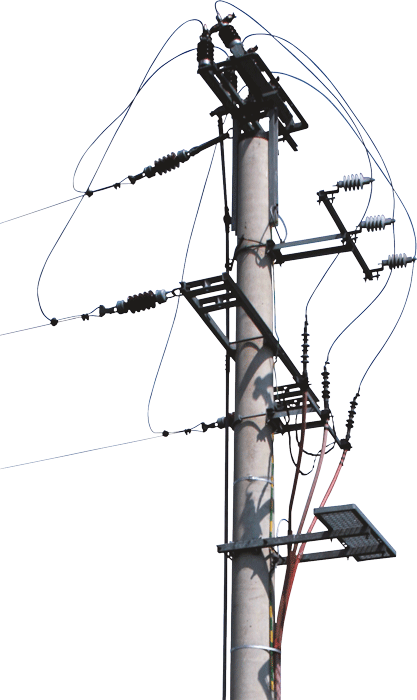

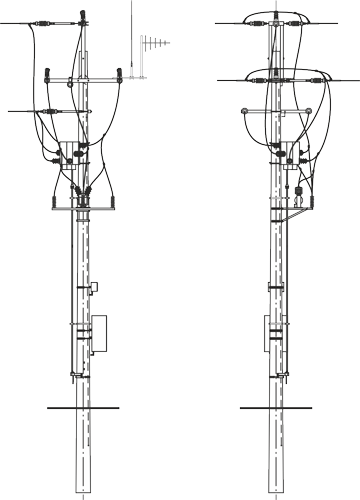

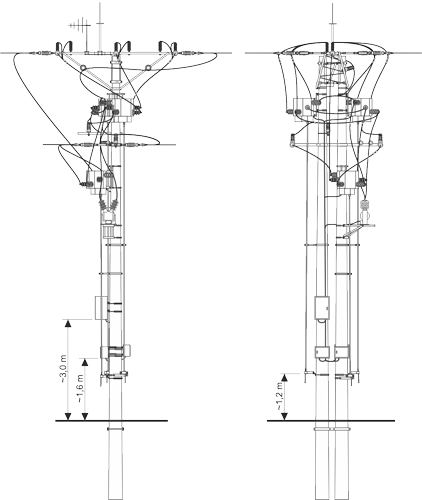

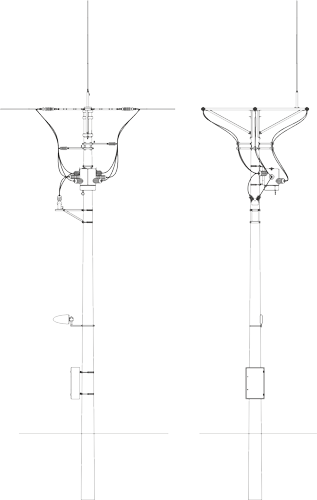

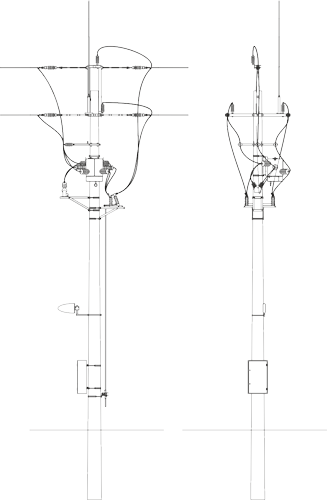

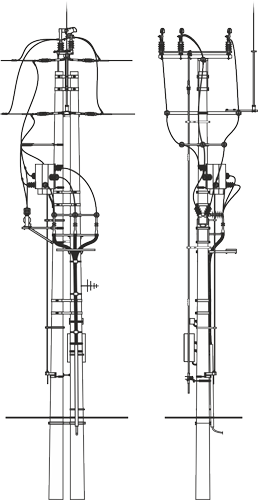

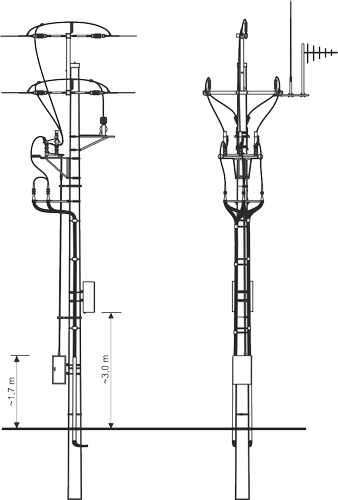

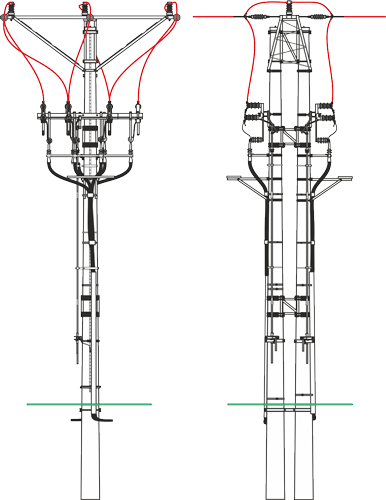

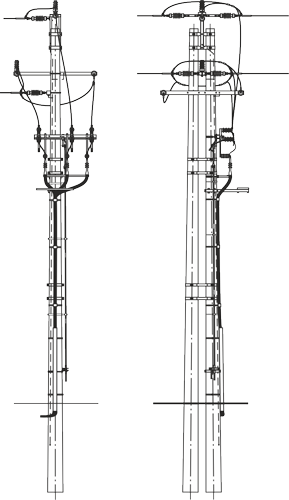

15-30 kV Overhead power lines with AFL-6 (35-70) cables on E spun concrete poles. Energoprojekt Poznań 1993 P-22505 volume 1-10 LSN/E

15-30 kV Overhead power lines with AFL-6 (35-70) cables on EPV spun concrete poles. Energoprojekt Poznań 1992 P-22529 volume 1-7 LSN/V

Medium voltage overhead power lines with AFL 35-70 cables on PTPIREE spun concrete poles, ELprojekt, Energolinia Poznań 1996 volume 1-8 LSN/P

15-20 kV Medium voltage overhead power lines with 70 (50) naked cables on spun concrete poles. Flat cable line. PTPIREE, Energolinia Poznań 2000 volume 1-8 LSN 50/E

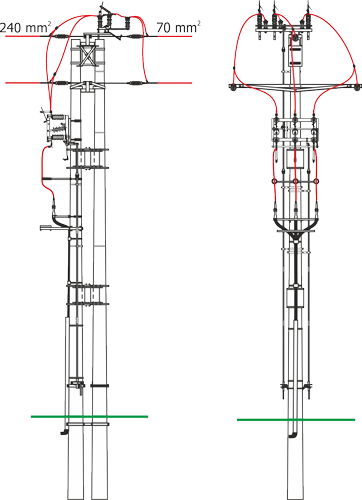

Medium voltage overhead power lines with AFL 95-240 cables on spun concrete poles Energolinia Poznań 1998 EN-118 volume 1-2 LSN 240/E

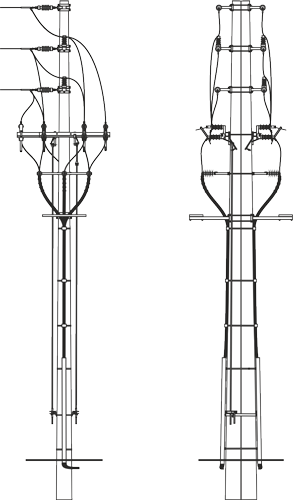

Medium voltage overhead power lines with PAS 50-120 cables on spun concrete poles. Flat and vertical cable line. Energolinia Poznań 1998 EN-029 volume 1-6 LSN/PAS

15-20 kV Medium voltage overhead power lines with 35 (50), 70 (120) insulated cables on spun concrete poles. Vertical and flat cable line Elprojekt Poznań 1996 volume 1-16 LSNi

Medium and low voltage overhead insulated lines on wooden and spun concrete poles – dual-voltage PTPIREE power lines , Energolinia, Elprojekt Poznań 1996 volume 1-7 LSN/LNN

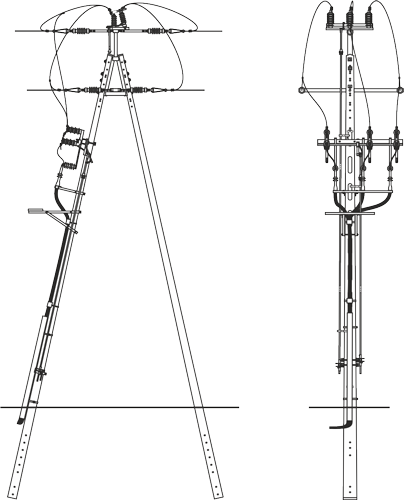

Medium voltage overhead power lines with AFL 35-70 naked cables on wooden poles. Triangular cable line. PTPIREE, Energolinia Poznań 2001 volume 1-3 LSNd

15-20 kV Medium voltage overhead power lines with semi-insulated cables with cross-sections 50-120mm2 in flat configuration on PTPIRE spun concrete poles, Elprojekt, Energolinia Poznań 2003 volume 1-8 LSNi 50- 120

15-20 kV Medium voltage overhead power lines with AFL 120(70) cables on spun concrete poles El- project Poznań 1994 volume 1-4 LSN 120/E Actualisation PTPIREE, El-project Poznań 1998 volume 1-4 LSN 120/E

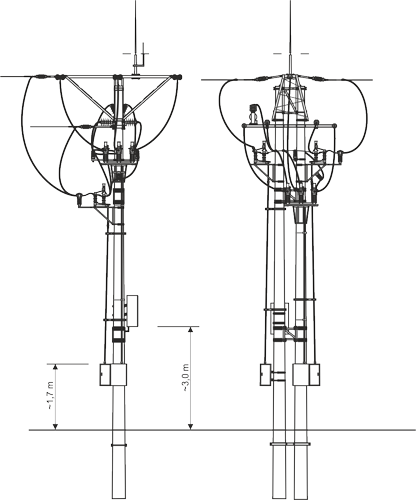

Medium voltage overhead power lines on spun concrete poles. Metering points catalogue (accounting) AFL 35-70 Energolinia Poznań1997 EN-067 volume 1-2 LSN/PR

15-20 kV Medium voltage overhead power lines on spun concrete poles. Metering points album. PTPIREE, Energolinia Poznań 2008 LSN/PR

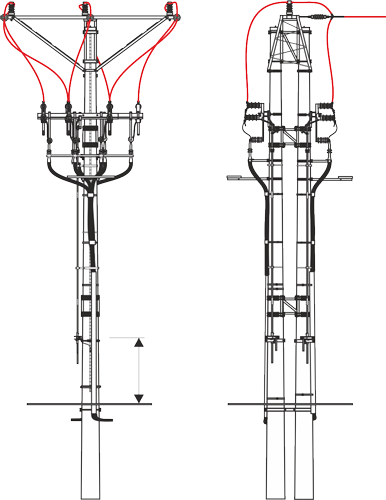

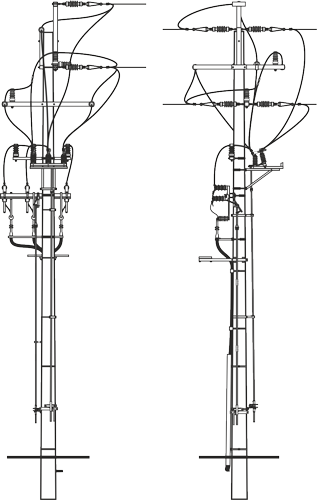

15-20 kV Medium voltage overhead power lines with 35 (50) and 70 mm2 naked cables on spun concrete poles with radio controlled switch disconnectors. PTPIREE, Elprojekt, Energolinia Poznań 2000 volume 1-3 LSN-os

15-20 kV Medium voltage overhead power lines with naked cables in triangular configuration on PTPIREE spun concrete poles, Energolinia Poznań 2002 volume 1-4 LSN 35(50)

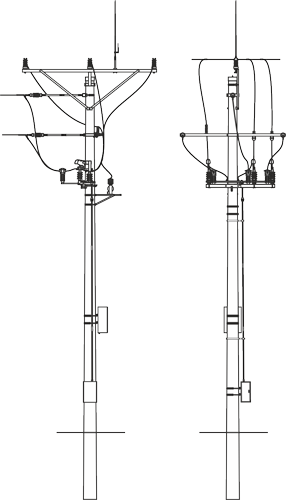

Medium voltage double track lines with AFL 120 (70) cables on PTPIREE spun concrete poles, Elprojekt Poznań 1995 volume 1-3 LSN 2 x 120/E

Medium voltage overhead double track lines with semi-insulated 2x70-120mm2 cables in vertical configuration on PTPIREE spun concrete poles, Elprojekt Poznań 2004 volume 1-3 LSNi 2x70-120

15-20 kV Medium voltage overhead power lines with unisolated cables in flat configuration 70 and 50mm2 on single spun concrete poles type E and EM Energolinia Poznań 2007 EN-340 volume 1-3 LSN 70(50)

15-30 kV Medium voltage overhead power lines on E, EPV, ŻN, BSW spun concrete poles. Catalogue of the poles with THO (AFL 35 70)switch disconnectors Energolinia Poznań 1997 EN-097 volume 1 LSN/R

15-30 kV Medium voltage overhead power lines on ŻN, BSW concrete poles, E and EPV spun concrete poles, with unisolated and insulated cables.

15-30 kV Medium voltage overhead power lines with AFL-6 120, 240mm2 cables in flat and triangular configuration on spun concrete poles Energolinia Poznań EN-316 2010 volume 1-2 LSN 120, 240