The TPM Air switchgear is a modern ring main unit (RMU) designed for use in medium-voltage networks. The design is based on dry air insulation and vacuum technology, using only natural components of atmospheric air, which ensures full compliance with current environmental requirements and future regulations on greenhouse gases. TPM Air meets the requirements for distribution switchgear, combining environmental considerations with the advantages of the proven TPM switchgear concept. It is a groundbreaking solution that guarantees safe, economical and long-term operation of MV networks.

Characteristics

Characteristics

- miniature switchgear dimensions while maintaining high technical parameters,

- high level of operational safety thanks to a design that ensures resistance to internal arcing on all sides of the switchgear,

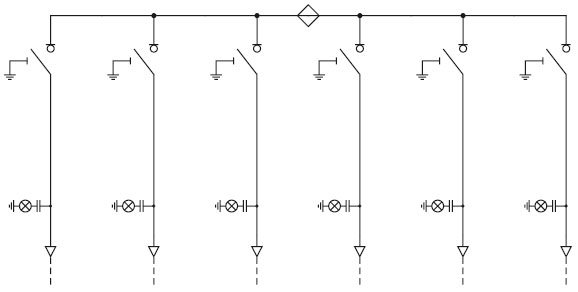

- possibility of configuring a switchgear from a series of panels for various purposes: line panels, transformer panels, switch panels, coupling panels, measuring panels,

- the switchboard can be easily expanded with additional sets (this should be taken into account when placing an order); each set can be manufactured as expandable,

- the possibility of adapting the switchgear to work with remote control and measurement systems, e.g. to work with SmartGrid networks,

- a quick earthing device that grounds the fuse link on both sides in the transformer field,

- tank made of stainless and acid-resistant steel, filled with dry air under overpressure; thanks to its sealed design, it does not require maintenance throughout its entire service life,

- insulating medium consisting of natural components of atmospheric air – no global warming potential (GWP).

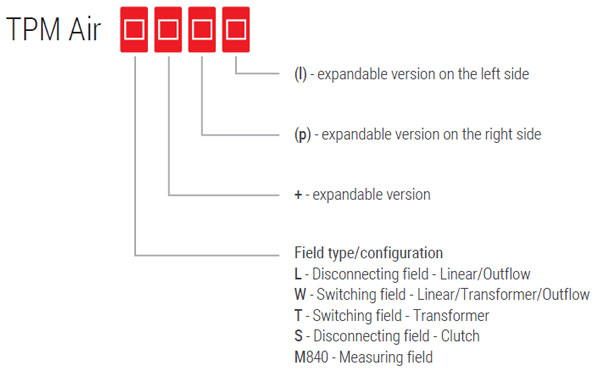

Possible markings/nomenclature

Standards

The TPM Air switchgear complies with the requirements of the following standards:

- PN-EN 62271-1 - „High-voltage switchgear and controlgear – Part 1: Common provisions”,

- PN-EN 62271-200 - „High-voltage switchgear and controlgear – Part 200: AC switchgear in metal enclosures for rated voltages above 1 kV up to and including 52 kV”,

- PN-EN 62271-100 - „High-voltage switchgear and controlgear – Part 100: High-voltage alternating current circuit breakers”,

- PN-EN 62271-102 - „High-voltage switchgear and controlgear – Part 102: High-voltage AC disconnectors and earthing switches”,

- PN-EN 62271-103 - „High-voltage switchgear and controlgear – Part 103: Disconnectors with a rated voltage exceeding 1 kV up to and including 52 kV”,

- PN-EN 62271-105 - „High-voltage switchgear and controlgear – Part 105: AC fuse switchgear assemblies”,

- PN-EN 62271-213 - „High-voltage switchgear and controlgear – Part 213: Voltage detection and indication system”.

Field equipment

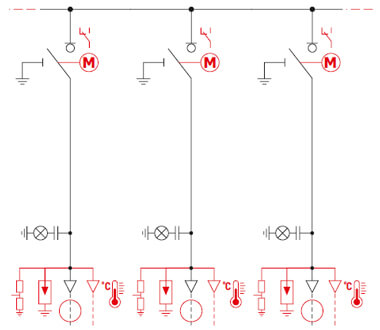

L-field equipment – disconnectors (line, supply, outlet)

| Basic parameters | |

| Ur | 25 kV |

| Fr | 50/60 Hz |

| Ud | 50/60 kV |

| Up | 125/145 kV |

| Ir | 630 A |

| Ik | up to 20 kA (1s) |

| Ip | up to 50 kA |

| Ima | up to 50 kA |

| Icc2 | 70 A |

| M2, E3, C2 disconnector class | |

| M1, E2 earthing switch class | |

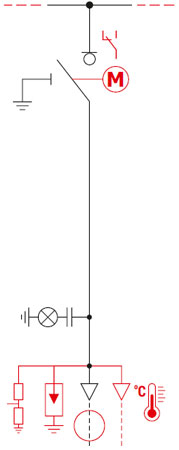

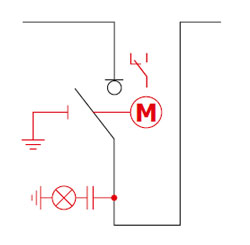

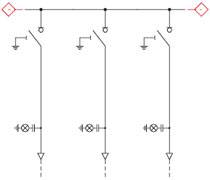

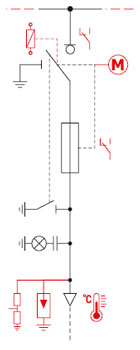

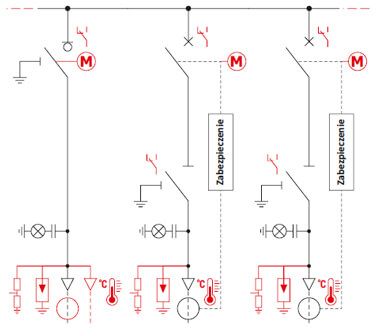

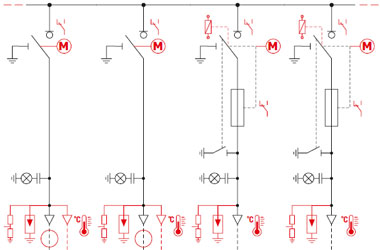

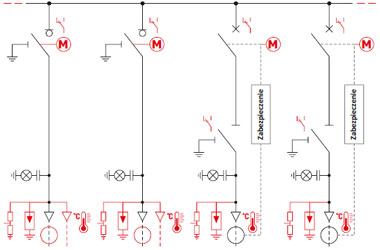

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

- compliance with PN-EN 62271-103, Disconnectors with rated voltage above 1kV up to and including 52kV,

- compliance with PN-EN 62271-102, High-voltage AC disconnectors and earthing switches,

- L field as a single module with an expansion option or can be combined with other configurations within a common tank in systems with up to four fields,

- three-position disconnector-earthing switch assembly, whose design is based on common moving contacts and separate fixed contacts of the earthing switch and disconnector,

- disconnector equipped with a shunt current interruption system in a vacuum chamber during disconnection,

- a manual drive ensuring intuitive and easy manoeuvring and quick closing and opening of the switching equipment,

- a synoptic display showing the status of the devices and entire main circuits,

- C-type bushings with M16 thread equipped with capacitive voltage dividers designed to work with voltage indicators in the LRM system and with electromagnetic interlocks,

- signal indicator of voltage presence on the cable in the LRM system,

- pressure gauge – gas pressure indicator with a two-zone scale, indicating the nominal absolute gas pressure (dry air) of -250 kPa (0.25 MPa) at a temperature of 20°C (one per tank),

- a system of mechanical locks between the devices and the cable compartment covers to prevent incorrect connection operations – the cover can only be removed after the earthing switch has been closed,

- safety valve (one for each tank), which opens when the pressure inside the tank rises due to an arc, directing the gases downwards into the cable duct, thus eliminating the risk to personnel,

- cable holders.

- 24V DC motor drive (other supply voltages available on request), can be retrofitted on site,

- pressure sensor (density meter) with auxiliary contacts – for use with motor drive, telemechanics,

- auxiliary contacts enabling the mapping of device statuses in telemechanics systems,

- voltage sensors - low-power transformers,

- current transformers, current sensors, Rogowski coils,

- earth fault transformers,

- short-circuit current flow indicators,

- auxiliary circuit cabinet/cooperation with telemechanics,

- ‘ON’ and ‘OFF’ signalling in the form of indicator lights,

- anti-condensation heaters,

- expansion possible on the right and left sides,

- key lock for disconnector or earthing switch socket,

- electromagnetic lock for earthing switch socket,

- surge arresters,

- AST-05 wireless temperature sensors, which are part of the eTemp system.

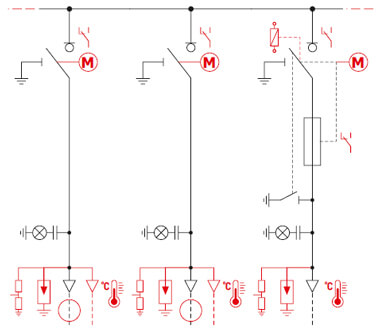

T-field equipment – disconnectors with fuses

| Podstawowe parametry | |

| Ur | 24 kV |

| fr | 50/60 Hz |

| Ud | 50/60 kV |

| Up | 125/145 kV |

| Ir | 250 A (125 A insert) |

| Ima | 5 kA (earthing conductor) |

| Itransfer | 1250 A |

| M2, E3 disconnector class | |

| M1, E2 earthing switch class | |

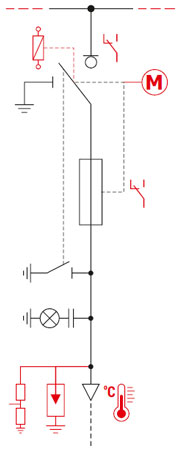

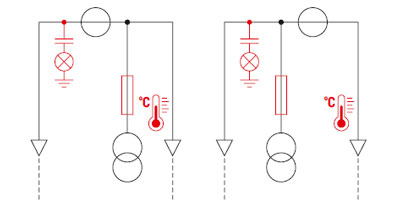

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

- compliance with PN-EN 62271-105 – AC fuse switchgear assemblies,

- compliance with PN-EN 62271-102, AC high-voltage disconnectors and earthing switches,

- T-field as a single module with an expansion option or can be combined with other configurations within a common tank in systems with up to four fields,

- three-position disconnector-earthing switch assembly, whose design is based on common moving contacts and separate fixed contacts of the earthing switch and disconnector,

- lower earthing switch ensuring earthing on both sides of the inserts,

- a disconnector equipped with a shunt current interruption system in a vacuum chamber during disconnection,

- a manual drive ensuring intuitive and easy manoeuvring and quick closing and opening of the switching equipment,

- synoptic display showing the status of devices and entire main circuits,

- storage drive function, which opens the disconnector contacts when MV inserts with thermal protection (blowout) or a release coil are used,

- insert burnout indicator,

- type A bushing insulators with plug-in socket, equipped with capacitive voltage dividers designed to work with voltage indicators in the LRM system,

- voltage presence indicator on the cable in the LRM system,

- pressure gauge - gas pressure indicator with a two-zone scale indicating the nominal absolute gas pressure (dry air) -250 kPa (0.25 MPa) at a temperature of 20°C (one per tank),

- a system of mechanical locks between the devices and the cable compartment cover, preventing incorrect connection operations - the cover can only be removed after the earthing switch has been closed,

- safety valve (one per tank), which opens as a result of pressure increase caused by an arc inside the tank, directing gases downwards into the cable duct,

- cable holders.

- 24V DC motor drive (other supply voltages available on request),

- pressure sensor (density meter) with auxiliary contacts – for cooperation with motor drive, telemechanics,

- auxiliary contacts as a representation of device statuses for telemechanics systems,

- fuse links equipped with a temperature limiter (thermal release) according to IEC 60282-1, DIN 43625,

- voltage sensors – low-power transformers,

- “ON” and “OFF” signalling in the form of indicator lights,

- anti-condensation heaters,

- C-type feed-through insulators with M16 thread equipped with capacitive voltage dividers designed to work with voltage indicators in the LRM system,

- possibility of expansion on the right and left sides,

- key lock for the disconnector or earthing switch socket,

- incremental trigger – DWN 24 V DC, 230V AC/DC coil (other voltages on request),

- AST-05 wireless temperature sensors, which are part of the eTemp system.

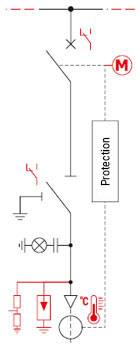

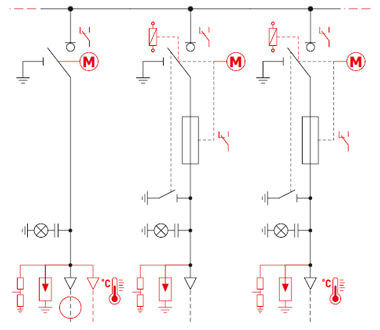

W field equipment – circuit breakers (power supply, outlet, transformer)

| Basic parameters | |

| Ur | 24 kV |

| fr | 50/60 Hz |

| Ud | 50/60 kV |

| Up | 125/145 kV |

| Ir | 630 A |

| Ik | up to 20 kA (1s) |

| Isc | up to 20 kA |

| Ief1 | up to 20 kA |

| Ima | up to 50 kA |

| Icc2 | 31,5 A |

| M2, E2, C2 disconnector class Switching range (O-0,3s-CO-15s-CO) |

|

| earthing switch class M1, E2 | |

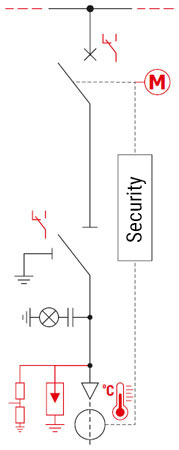

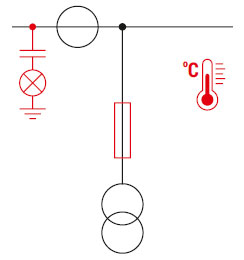

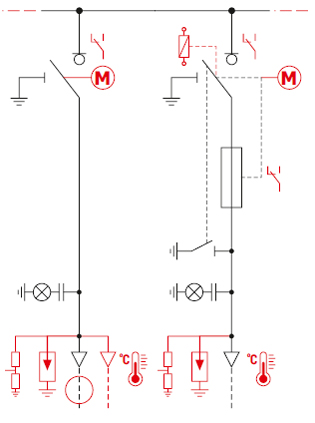

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

- compliance with PN-EN 62271-100, High-voltage alternating current circuit breakers,

- compliance with PN-EN 62271-102, High-voltage alternating current disconnectors and earthing switches,

- W field as a single module with an expansion option or can be combined with other configurations within a common tank in systems with up to four fields,

- a circuit breaker assembly based on the use of vacuum chambers with a breaking current of 16kA or 20kA enclosed in a tank filled with dry air,

- a three-position disconnector-earthing switch assembly, whose design is based on common moving contacts and separate fixed contacts of the earthing switch and disconnector. The function of the disconnector is to ensure a safe break in the circuit,

- a manual spring drive for the circuit breaker, ensuring intuitive and easy manoeuvring as well as instantaneous closing and opening of the switching equipment; the drive has a circuit breaker arming system allowing for a fast on-off cycle,

- Manual drive of the three-position disconnector-earthing switch ensuring intuitive and easy manoeuvring of the switching equipment.

- Synoptic diagram showing the status of the devices and entire main circuits.

- circuit breaker arming signalling,

- autonomous protection, preferably AZZ-4 (manufactured by ITR) or WIC 1 (manufactured by SEG) with dedicated current transformers,

- C-type bushing insulators with M16 thread equipped with capacitive voltage dividers designed to work with voltage indicators in the LRM system and with electromagnetic locks,

- signal indicator of voltage presence on the cable in the LRM system,

- pressure gauge - gas pressure indicator with a two-zone scale indicating the nominal absolute gas pressure (dry air) -250 kPa (0.25 MPa) at a temperature of 20°C (one per tank),

- a system of mechanical locks between the devices and the cable compartment covers to prevent incorrect connection operations - the cover can only be removed after the earthing switch has been closed,

- safety valve (one per tank), which opens when the pressure inside the tank rises due to an arc, directing the gases downwards into the cable duct, thus eliminating the risk to personnel,

- cable voltage indicator,

- cable holders.

- 24V DC motor drive for the switch (other supply voltages available on request),

- pressure sensor (density meter) with auxiliary contacts – for cooperation with motor drive, telemechanics,

- auxiliary contacts as a representation of device states for telemechanics systems,

- safety devices other than the preferred autonomous ones, field controllers, SZR automation,

- voltage sensors - low-power transformers,

- current transformers, current sensors, Rogowski coils, earth fault transformers,

- auxiliary circuit cabinet/cooperation with telemechanics,

- ‘ON’ and ‘OFF’ signalling in the form of indicator lights,

- anti-condensation heaters,

- expansion possible on the right and left sides,

- surge arresters,

- AST-05 wireless temperature sensors, which are part of the eTemp system.

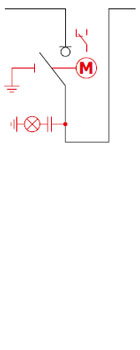

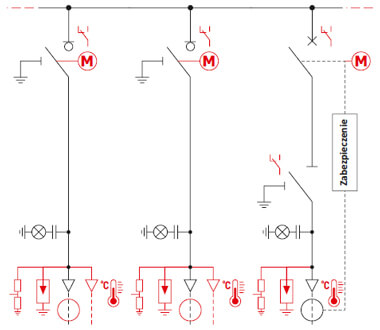

S-field equipment – disconnectors – couplers

| Basic parameters | |

| Ur | 24 kV |

| fr | 50/60 Hz |

| Ud | 50/60 kV |

| Up | 125/145 kV |

| Ir | 630 A |

| Ik | up to 20 kA (1s) |

| Ip | up to 50 kA |

| Ima | up to 50 kA |

| M2, E3 disconnector class | |

| M1, E2 earthing switch class | |

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

- compliance with PN-EN 62271-103, Disconnectors with rated voltage above 1kV up to and including 52kV,

- compliance with PN-EN 62271-102, High-voltage AC disconnectors and earthing switches,

- S field as a single module expandable to the right and left,

- disconnector based on common moving contacts and fixed contacts,

- arc extinguishing system during switching operations,

- manual drive ensuring intuitive and easy manoeuvring as well as quick closing and opening of switching equipment,

- synoptic display showing the status of devices and entire main circuits,

- pressure gauge - gas pressure indicator with a two-zone scale showing the nominal absolute pressure of the gas (dry air) -250 kPa (0.25 MPa) at a temperature of 20°C,

- safety valve (one per tank), which opens when the pressure inside the tank rises due to an arc, directing the gases downwards into the cable duct, thus eliminating the risk to personnel.

- 24V DC motor drive (other supply voltages available on request), easy to install on site,

- main track earthing switch for the right section,

- voltage presence indicator on the main tracks before and after the disconnector,

- pressure sensor (density meter) with auxiliary contacts - for cooperation with the motor drive, telemechanics,

- auxiliary contacts enabling the mapping of device statuses in telemechanics systems,

- key lock for the disconnector or earthing switch socket.

M-field equipment - measurement

| Basic parameters | |

| Ur | 24 kV |

| fr | 50/60 Hz |

| Ud | 50/60 kV |

| Up | 125/145 kV |

| Ir | 630 A |

| Ik | up to 20 kA (1s) |

| Ip | up to 50 kA |

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

- compliance with PN-EN 62271-200, AC switchgear in metal enclosures for rated voltages above 1 kV up to and including 52 kV,

- M840 field as a single module expandable to the right and left,

- busbar system enclosed in a stainless steel tank,

- set of voltage and current transformers,

- voltage presence indicator on main circuits,

- synoptic diagram with main circuit mapping,

- pressure gauge - gas pressure indicator with a two-zone scale indicating the nominal absolute pressure of the gas (dry air) -250 kPa (0.25 MPa) at a temperature of 20°C,

- safety valve (one per tank), which opens when the pressure inside the tank rises due to an arc, directing the gases downwards into the cable duct, thus eliminating the risk to personnel.

- anti-condensation heaters,

- AST-05 wireless temperature sensors, which are part of the eTemp system.

Safety

Safety

- The robust construction of TPM Air switchgear guarantees high reliability.

- The tank is made of stainless and acid-resistant steel, which ensures resistance to environmental influences.

- The use of shielded heads guarantees safety, e.g. during maintenance work with the cover removed and voltage on the power cables.

- Gas (dry air) pressure gauge - manometer, indicating the correct pressure of the insulating gas inside the tank.

- resistance to internal arcing of 20 kA as standard,

- the pressure increase caused by internal arcing is eliminated by opening the safety valve installed at the bottom of the switchgear tank. The gases escape into the cable duct, which does not pose a hazard to the operating personnel,

- drives enabling manual switching of devices,

- each switchboard compartment is equipped with voltage indicators, allowing the operator to verify that there is no voltage on the bushings of the insulators,

- a clear synoptic diagram improving the intuitiveness of operation and reading of the status of devices,

- a set of mechanical locks allows the cable compartment covers to be opened only after the earthing switch has been closed,

- a set of mechanical locks between devices preventing incorrect switching operations,

- optional use of electromagnetic locks that prevent the earthing switch from closing in the event of voltage on the power cables,

- a set of auxiliary contacts with device status signal output, which guarantees the safety of remote operation,

- the use of a pressure switch in all cases with a motor drive option, which guarantees the safety of remote operation.

TPM Air MV switchgear compartments

Connector compartment

The switch compartment is located in a tank made of stainless and acid-resistant sheet metal. Dry air under overpressure, which has very high dielectric strength, is used as the insulating medium. Inside the tank there are busbars, insulators and switching equipment, which, depending on the configuration, may include a three-position disconnector-earthing switch with a shunt chamber, a three-position disconnector-earthing switch or a vacuum circuit breaker. Each tank has a safety valve, which, when opened, eliminates the pressure increase caused by an internal arc. In the TPM Air switchgear, the valve is located at the bottom of the tank in the cable connection compartment in one of the line bays. The bushing insulators have built-in capacitive voltage dividers connected to voltage indicators located on the front wall of the switchgear. Both the disconnector itself and the drive mechanisms are extremely durable and reliable devices.

Fuse compartment

Inserts equipped with a temperature limiter (thermal release) in accordance with IEC 60282-1, DIN 43625 are installed in the fuse compartment of the switchgear (in special insulating tubes) to prevent unacceptable high temperatures, regardless of their cause. The design of the fuse compartment prevents it from being opened before the temperature limiter is activated. DIN 43625, to prevent unacceptable high temperatures, regardless of their cause. The design of the fuse compartment prevents it from being opened before the earthing switch is closed. The disconnector in the transformer bay can only be switched on after the fuse compartment cover has been closed. If the fuse link blows, the knock-out device installed in it triggers the automatic opening mechanism of the disconnector in the transformer field. The disconnector can be switched on again after replacing the fuse links.

Drive compartment

The drive compartment includes an integrated, direct manual (motor) drive for the disconnector and earthing switch or vacuum circuit breaker. In addition, the transformer bay is equipped with a storage drive that allows the disconnector to be switched off after the fuse link has been tripped or when a release coil is used. The fuse link burnout status is indicated on the front panel of the drive. A pressure gauge (calibrated to the nominal state depending on the temperature) is located in the switchgear drive compartment to indicate the correct gas pressure inside the tank. Voltage indicators on the cable are located at the front of the switchgear.

Cable compartment

In the cable compartment, the switchgear is connected to the power network cables using cable heads. Individual cable compartment bays have metal partitions separating one bay from another.

Each cable compartment is equipped with:

- C-type bushing insulators for power supply, drainage and transformer fields equipped with a power switch,

- Type A bushing insulators for transformer fields equipped with MV fuses,

- cable clamps,

- grounding terminals for return conductors.

In addition, each field allows for the installation of the following equipment:

- protection transformers, Rogowski coils,

- voltage sensors,

- surge arresters,

- combined systems using deep covers, e.g.: two heads per phase, head + voltage sensor, head + surge arrester, two heads per phase + voltage sensor, two heads per phase + surge arrester, head + surge arrester + voltage sensor.

The TPM Air switchgear is designed for connecting cables with a cross-section of up to 630 mm², e.g. cables with plastic insulation, such as YHAKXS, YHKX, XUHAKXS or XRUHKS.

Technical data

| TPM Air switchgear rating data | ||

| LV rated voltage | Ur | 24 kV |

| Rated frequency - number of phases | fr | 50 / 60 Hz / 3 |

| Rated voltage at mains frequency | Ud | 50 kV / 60 kV |

| Withstand lightning impulse voltage (1.2/50 µs) | Up | 125 kV / 145 kV |

| Rated continuous current of main rails | Ir | 630 A |

| Rated short-time withstand current of main circuits | Ik | 16 kA (1s) / 20 kA (1s) |

| Rated peak current withstand of main circuits | Ip | 40 kA / 50 kA |

| Resistance to internal bowing | IA | 20 kA (1s) |

| IAC Class | AFLR | |

| IP protection rating | IP4X (IP54 option) | |

| Resistance to mechanical impact | Ik10 | |

| Environmental operating conditions: | |

| Ambient temperature | |

|

- peak short-term

|

+ 40°C

|

|

- highest average over a 24-hour period

|

+ 35°C

|

|

- minimum

|

|

|

- without secondary circuits

|

- 25°C

|

|

- with secondary circuits

|

- 5°C / - 15°C / - 25°C1)

|

| Relative air humidity | |

|

- highest average over a 24-hour period

|

95%

|

|

- highest average during the month

|

90%

|

| Vibrations | vibrations caused by external factors or earthquakes are negligible |

| Degree of protection (Internal Protection) | |

|

- apparatus compartment stainless steel tank

|

IP 67

|

|

- drive and connection compartment

|

IP 4X

|

| Contamination conditions | |

|

- Significant contamination with salt, vapours, dust, smoke, combustible gases

|

NONE

|

|

- Corrosive

|

NONE

|

|

- Icing, frosting, snow drifts

|

NONE

|

Note:

1) Provided that the manufacturer of the control, measurement and safety equipment has not specified otherwise.

| Rated parameters of a three-position isolating switch, line field (L) | ||

| Rated continuous current | Ir | 630 A |

| Rated short-circuit current | Ima | 50 kA |

| Rated current that can be switched off in a circuit with low inductance | Iload | 630 A |

| Rated current that can be switched off in loop circuit | Iloop | 630 A |

| Rated switchable charging current for cables | Icc2 | 70 A |

| Rated switchable line charging current | Ilc | 20 A |

| Rated short-circuit breaking current | Ief1 | 210 A |

| Rated breaking current for charging cables and lines under earth fault conditions | Ief2 | 121 A |

| Disconnector class | M2 (5 000 CO), E3, C2 | |

| Earthing switch class | M1, E2 | |

| Rated parameters of a three-position isolating switch in a set with fuses, transformer field (T) | ||

| Rated continuous current | Ir | 250 A |

| Maximum current of the fuse with thermal protection | 125 kA | |

| Passing current | Itransfer | 1250 A |

| Rated short-circuit current of the earthing switch | Ima | 5 kA |

| Electrical disconnector class | M2, E3 | |

| Maximum transformer power ratings | 6 kV | 800 kVA |

| 10 kV | 1000 kVA | |

| 15 kV | 1600 kVA | |

| 20 kV | 2000 kVA | |

| Rated parameters of the circuit breaker - circuit breaker field (W) | ||

| Rated continuous current | Ir | 630 A |

| Rated short-circuit current | Ima | 40 kA / 50 kA |

| Rated short-circuit breaking current | Isc | 16 kA / 20 kA |

| Rated earth fault tripping current | Ief1 | 16 kA / 20 kA |

| Rated current of an unloaded cable line | Icc2 | 31,5 A |

| Switch class | Ilc | M2 (10 000 CO), E2, C2 |

| Shift series | Ief1 | O-0,3s-CO-15s-CO |

The rated currents of fuse links recommended by leading manufacturers for protecting primary circuits of transformers with rated voltages of 6 kV, 10 kV, 15 kV and 20 kV should be selected in accordance with IEC 60282-1, DIN 43625 with a temperature limiter (thermal protection).

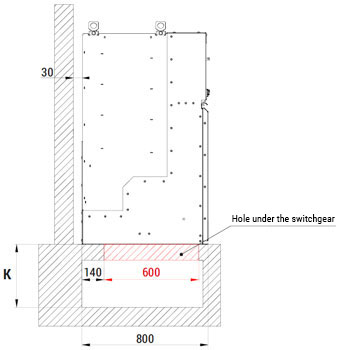

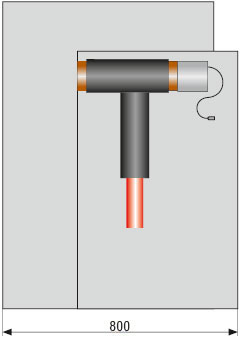

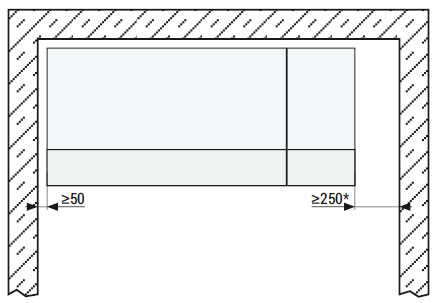

Method of constructing a cable duct under a TPM Air MV switchgear

The depth of the duct for dry cables should be selected taking into account the minimum bending radius specified in the technical specifications for the cable type, depending on its external diameter. An example of the recommended cable duct depth is shown in the illustration below. The use of a raised plinth or technical floor allows for the reduction or complete elimination of the need for a recessed channel.

| Single core dry cable | ||

| cable cross-section (mm2) | bending radius (mm) | channel depth K (mm) |

| 50 | 370 | 400 |

| 70 | 400 | 430 |

| 95 | 440 | 470 |

| 120 | 470 | 500 |

| 150 | 500 | 550 |

| 185 | 540 | 600 |

| 240 | 590 | 700 |

Cable heads

The TPM Air switchgear can be fitted with connection heads from all leading manufacturers of Cellpack, Nexans (Euromold) and TE Connectivity (Raychem) heads. A detailed list of heads to be used in MV switchgear is provided in the tables below.

| Line disconnectors (L) and circuit breakers (W) - Type C interface | ||||||

| Cable type | Note | |||||

| Manufacturer | Cable cross-section [mm2] |

Cable head |

Surge protector |

Voltage sensor |

||

| Single-core plastic cable, e.g. YHAKXs, YHKX, XUHAKXs, XRUHKs, ... |

Cellpack | 25-240 | CTS 630A | CTKSA | UR56 (ITR) | Cable cross-section > 240 mm2, more cables per phase, other types of cable heads should be consulted with the manufacturer. |

| Nexans | 25-240 | K480TB | 800PB–10SA | UR66 (ITR) | ||

| TYCO ELECTRONIC | 25-240 | RSTI | RSTI – CC | UR56 (ITR) | ||

| Transformer fields (T) - Type A interface | ||||

| Cable type | Cable accessories | Note | ||

| Manufacturer | Cable cross-section [mm2] |

Cable head |

||

| Single-core plastic cable, e.g. YHAKXs, YHKX, XUHAKXs, XRUHKs, ... |

Cellpack | 16-150 | CWS 250A | Cable cross-section > 240 mm2, more cables per phase, other types of cable heads should be consulted with the manufacturer. |

| Nexans | 25-150 | K200LR | ||

| TYCO ELECTRONIC | 35-70 | RSES 525 – B | ||

Note:

In all cases, a cable duct is required under the switchgear. Optionally, the switchgear can be placed on a pedestal or on a technical floor.

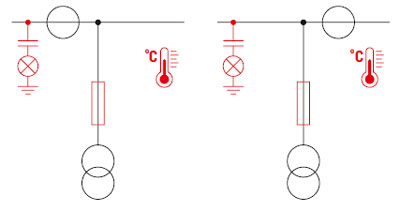

Connection options in the TPM Air switchgear – standard and deep cable cover

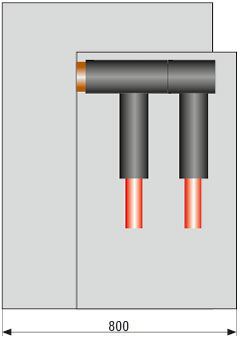

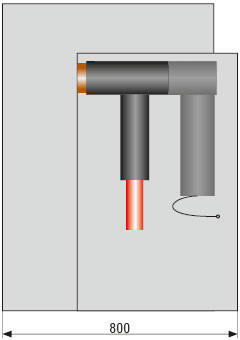

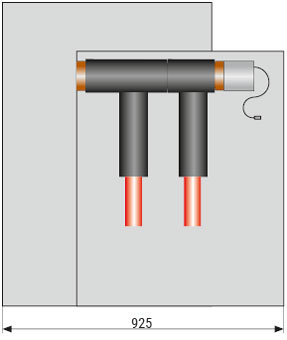

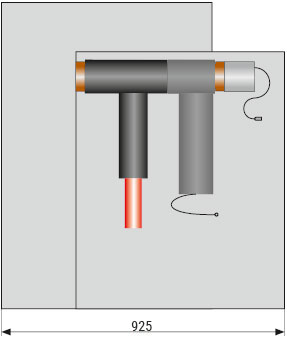

How to connect expandable sets

The TPM Air switchgear can be expanded with additional sets (provided that this has been discussed at the quotation and ordering stage). The connection methods are illustrated in the figures below. Detailed information can be found in the switchgear Technical and Operational Documentation.

* Minimum space required to install an additional module.

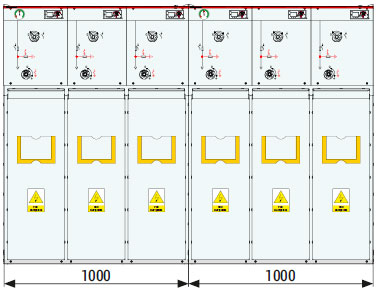

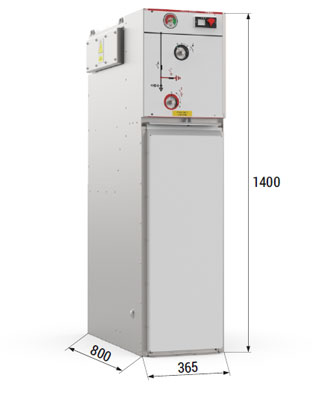

Typical configurations

Single fields

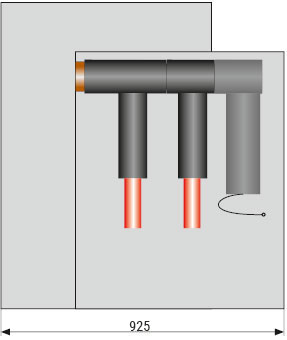

| Configuration | Width in mm | Depth in mm | Height in mm | |

| L | 365 | 800 | 925* | 1400 |

| T | 445 | 800 | 1400 | |

| W | 515 | 800 | 925* | 1400 |

| S | 490 | 800 | 1400 | |

* deepened cable compartment cover

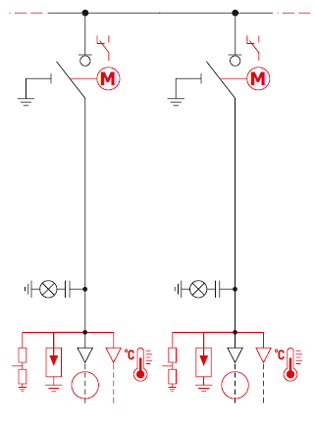

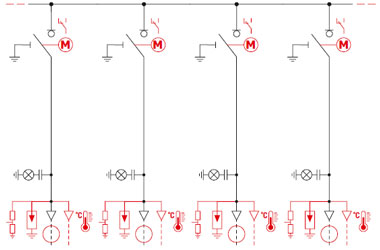

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

Two-pole system

| Configuration | Width in mm | Depth. in mm | Height in mm | |

| LL | 680 | 800 | 925* | 1400 |

| LT | 740 | 800 | 925* | 1400 |

| LW | 900 | 800 | 925* | 1400 |

* deepened cable compartment cover

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

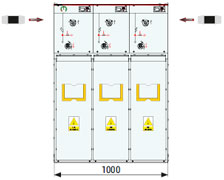

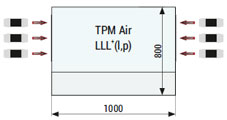

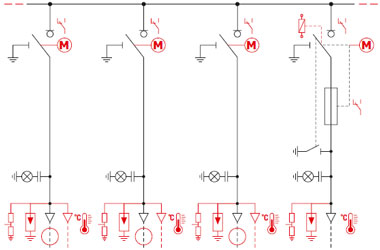

Three-pole system

| Configuration | Width in mm | Depth. in mm | Height in mm | |

| LLL | 1000 | 800 | 925* | 1400 |

| LLT | 1055 | 800 | 925* | 1400 |

| LLW | 1130 | 800 | 925* | 1400 |

* deepened cable compartment cover

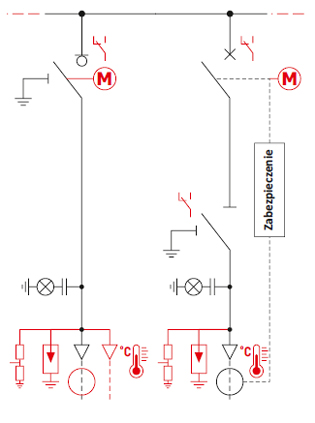

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

| Configuration | Width in mm | Depth in mm | Height in mm | |

| LTT | 1100 | 800 | 925* | 1400 |

| LWW | 1200 | 800 | 925* | 1400 |

* deepened cable compartment cover

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.

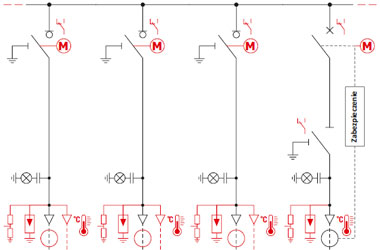

Four-pole circuit

| Configuration | Width in mm | Depth. in mm | Height in mm | |

| LLLL | 1315 | 800 | 925* | 1400 |

| LLLT | 1375 | 800 | 925* | 1400 |

| LLLW | 1450 | 800 | 925* | 1400 |

| LLTT | 1425 | 800 | 925* | 1400 |

| LLWW | 1550 | 800 | 925* | 1400 |

Optional equipment is marked in red on the wiring diagram.

Some optional equipment may be mutually exclusive or require the use of a deep cable compartment cover.