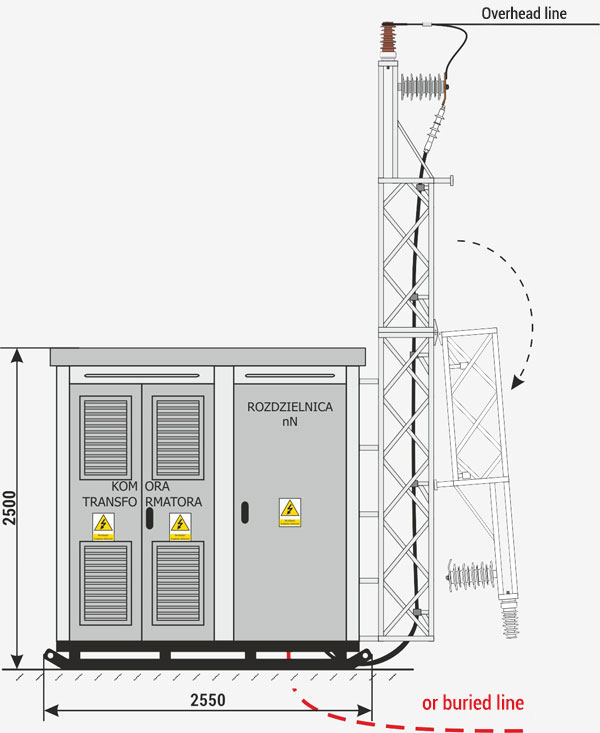

Substation dedicated for emergency power supply, with the possibility of being supplied from an overhead or buried line.

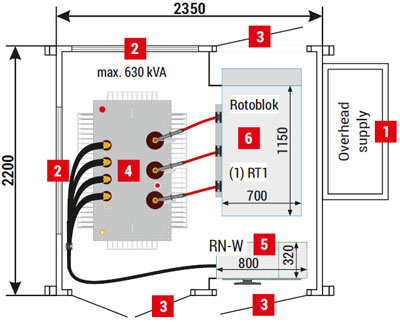

Placement of equipment

MRw 20/630-1

| 1 | Overhead connection |

| 2 | Ventilation louvres IP 23D - standard or IP 43 - option |

| 3 | Doors: solid or with ventilation louvres IP 23D - standard, or IP 43 - option |

| 4 | Transformer |

| 5 | LV switchgear |

| 6 | MV switchgear |

Note!

The catalogue presents example substation configurations.

Technical parameters / configuration possibilities

| Mass / Area | |

| Main structure | 2 400 kg |

| Usable area | 4,73 m2 |

| Technical parameters / configuration possibilities | |||

| Transformer (4) Maximum power / dimension* | 630 kVA / 1000 x 1800 x 1850 [mm] | ||

| Internal arc resistance classification | IAC-AB-16 kA-1s | ||

| Enclosure class | 20 | ||

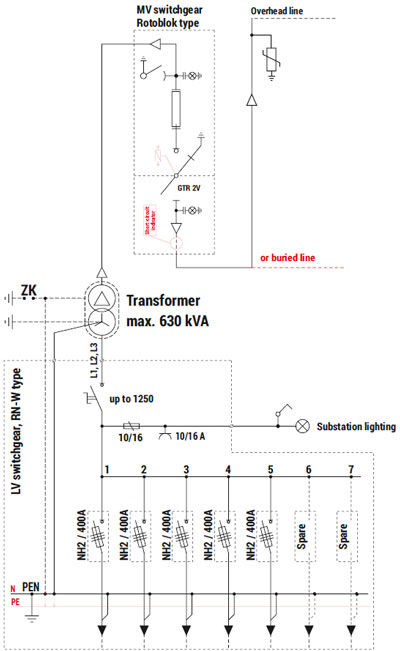

| Electrical parameters of switchgears | MV | LV | |

| Rated voltage | up to 25 kV | up to 0,69 kV | |

| Rated current | 630 A | up to 1250 A | |

| Rated short-time withstand current | up to 20 kA (1s) | up to 20 kA (1s) | |

| Rated peak withstand current | up to 50 kA | up to 50 kA | |

| Switchgear** | Typ | Maximum number of bays | |

| LV (5) | RN-W | 7 | |

| MV (6) | Rotoblok (700) | 1 (RT1) | |

* Maximum width of the transformer installed through the substation doors.

** Detailed selection of switchgears and their equipment is listed in chapters dedicated to individual devices in the catalogue.

Example layouts of switchgears and corresponding substation configurations are specified in parentheses.