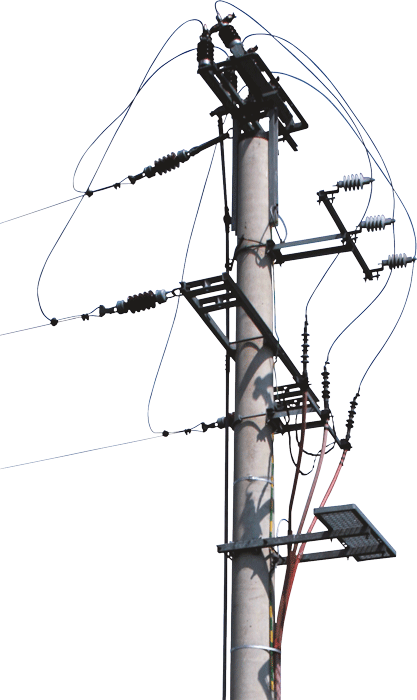

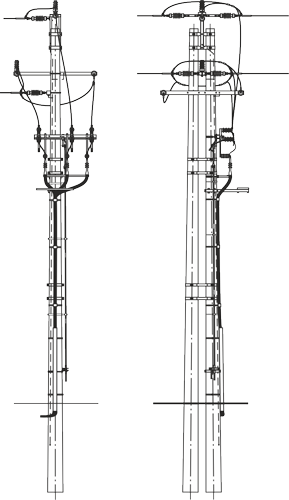

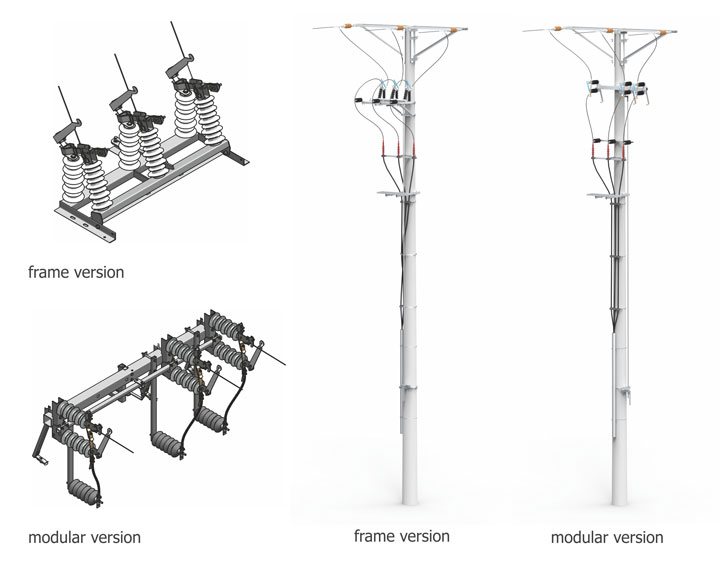

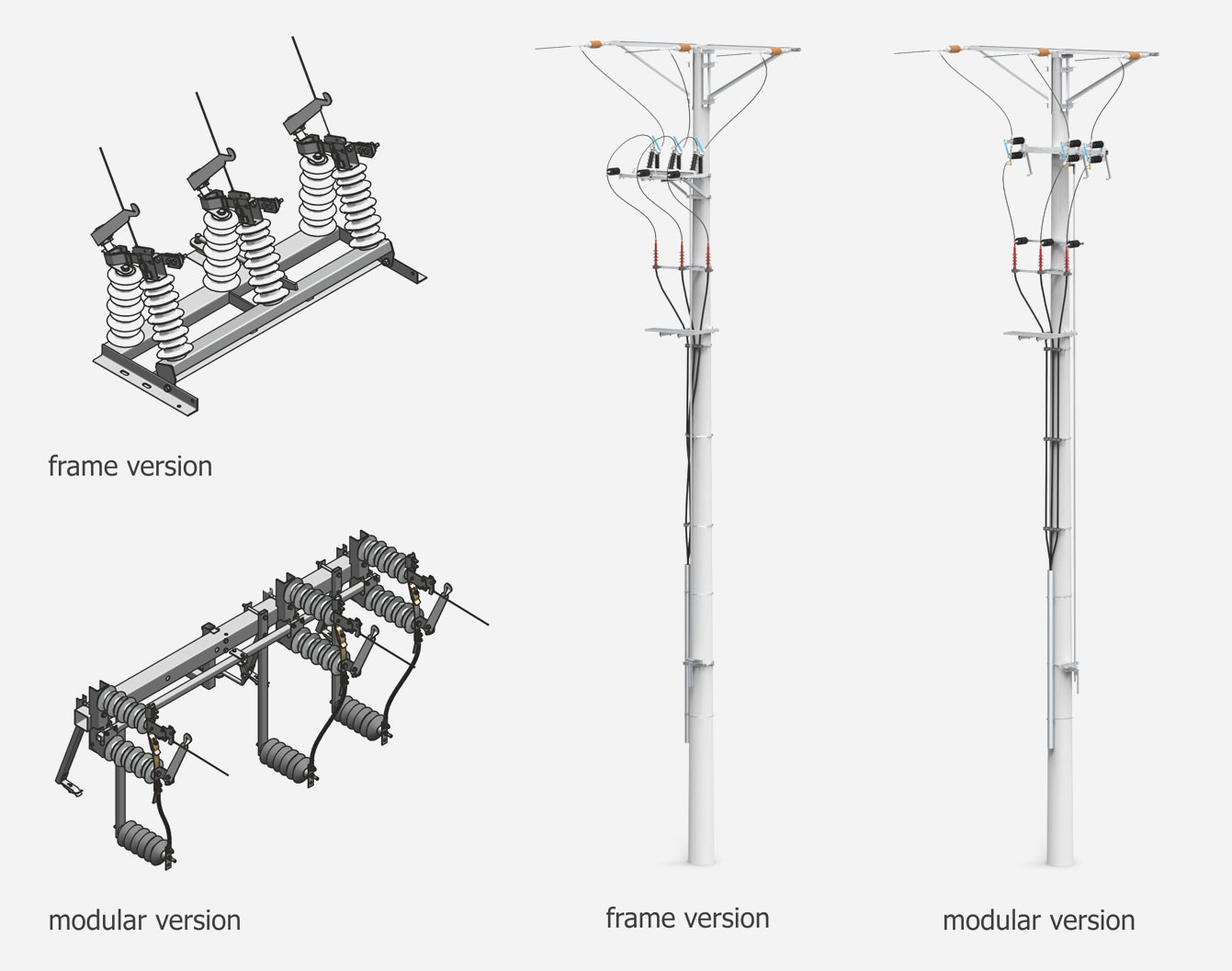

The pre-stressed high strength type E and EM concrete poles offered by ZPUE are the highest quality products, compliant with the standard PN-EN 12843:2008. Use of modern technology of concrete density by centrifugation method allows us to achieve a high level of density and a smooth surface, which guarantees the stability and bearing capacity of the spun concrete poles. Concrete compressive strength class minimum C40/50(C50/60) according to PN-EN206-1:2003.

Characteristics

- design working life 50 years without the need for maintenance,

- low water absorption <3,5%, good frost resistance, exposure class XC4, XF2 according to the PN-EN 206-1 norm: 2003, confirmed by accredited research body,

- esthetic design, scratch resistance of the smooth surface,

- limiting of the amount of land made unavailable for agricultural use

- possibility to increase the span length, fewer number of poles along 1km of lines,

- easy foundation in the ground,

- application of one concrete pole instead of expanded spans.

Application:

- supports for overhead and overhead-cable MV and LV power lines, telecommunication lines, train and tram lines,

- various support constructions for general application.

Spun poles type E and EM have a Certificate of Factory Production Control 1487 CPD/112/ZKP/09

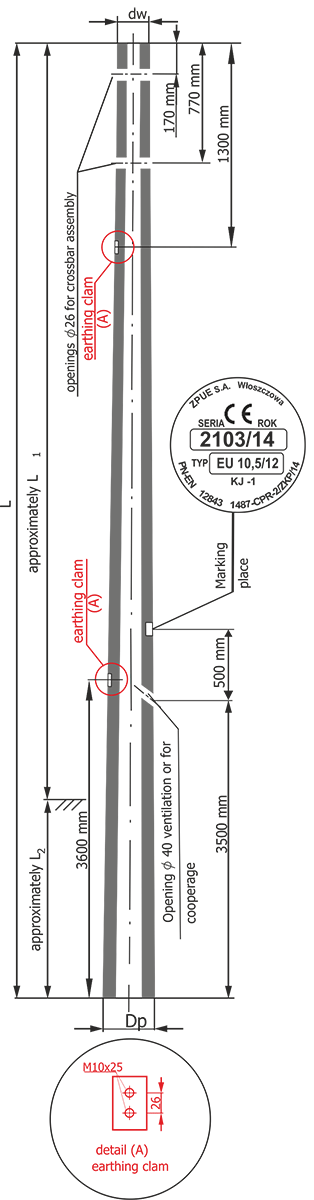

Technical parameters of the concrete pole type E and EM

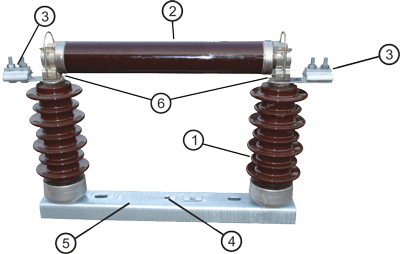

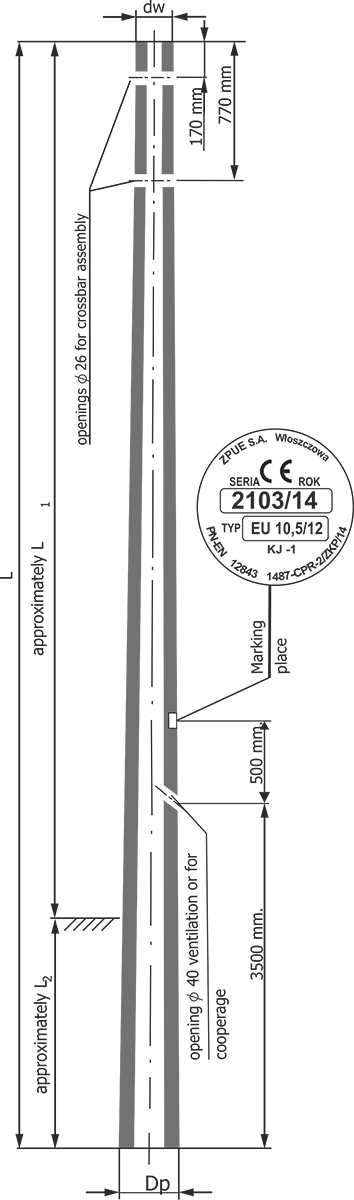

Legend:

L - overall length of the concrete pole

dw - outside diameter of the apex

dp - outside diameter of the base

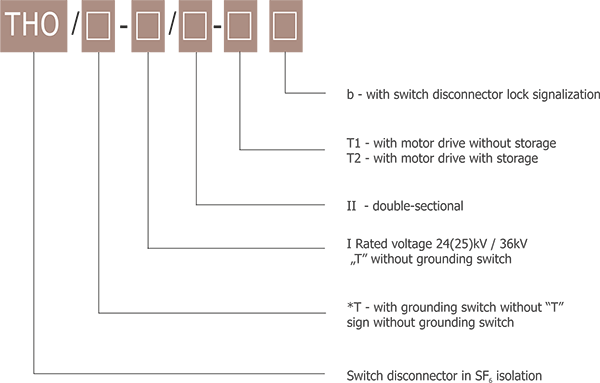

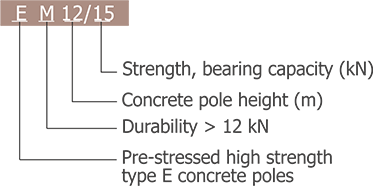

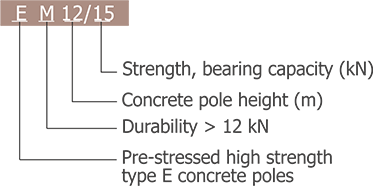

Concrete poles designation

| Technical parameters of the concrete pole type E | ||||||||||

| Lp. | Concrete pole type |

Strength [kN] |

Repture force [kg] |

Weight [kg] |

Dimensions | Strength colour indication |

||||

| [m] | [mm] | |||||||||

| L | L1 | L2 | dp | dw | ||||||

| 1 | E 6,7/12 | 12 | 21,6 | 910 | 6,7 | 6,7 | 1,5 | 353 | 218 |  |

| 2 | E 7,5/12 | 12 | 21,6 | 1055 | 7,5 | 6,7 | 1,5 | 330 | 218 |  |

| 3 | E 8,2/4,3 | 4,3 | 7,7 | 990 | 8,2 | 6,7 | 1,5 | 353 | 218 |  |

| 4 | E 8,2/6 | 6,0 | 10,8 | 990 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 5 | E 8,2/10 | 10,0 | 18,0 | 1100 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 6 | E 8,2/12 | 12,0 | 21,6 | 1150 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 7 | E 8,2/15 | 15,0 | 27,0 | 1150 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 8 | E 9/2,5 | 2,5 | 4,5 | 775 | 9,0 | 7,4 | 1,6 | 308 | 173 |  |

| 9 | E 9/4,3 | 4,3 | 7,7 | 845 | 9,0 | 7,4 | 1,6 | 308 | 173 |  |

| 10 | E 9/6c | 6,0 | 10,8 | 845 | 9,0 | 7,4 | 1,6 | 308 | 173 |  |

| 11 | E 9/6 | 6,0 | 10,8 | 1250 | 9,0 | 7,7 | 1,6 | 353 | 218 |  |

| 12 | E 9/10 | 10,0 | 18,0 | 1300 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 13 | E 9/12 | 12,0 | 21,6 | 1300 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 14 | E 9/15 | 15,0 | 27,0 | 1380 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 15 | E 9/20 | 20,0 | 36,0 | 1508 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 16 | E 10,5/2,5 | 2,5 | 4,5 | 1100 | 10,5 | 8,7 | 1,8 | 330 | 173 |  |

| 17 | E 10,5/4,3c | 4,3 | 7,7 | 1100 | 10,5 | 8,5 | 2,0 | 330 | 173 |  |

| 18 | E 10,5/4,3 | 4,3 | 7,7 | 1500 | 10,5 | 8,5 | 2,0 | 375 | 218 |  |

| 19 | E 10,5/6c | 6,0 | 10,8 | 1100 | 10,5 | 8,5 | 2,0 | 330 | 173 |  |

| 20 | E 10,5/6 | 6,0 | 10,8 | 1500 | 10,5 | 8,5 | 2,0 | 375 | 218 |  |

| 21 | E 10,5/10 | 10,0 | 18,0 | 1600 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 22 | E 10,5/12 | 12,0 | 21,6 | 1650 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 23 | E 10,5/15 | 15,0 | 27,0 | 1725 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 24 | E 10,5/20 | 20,0 | 36,0 | 1878 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 25 | E 12/2,5 | 2,5 | 4,5 | 1400 | 12,0 | 10,0 | 2,0 | 353 | 173 |  |

| 26 | E 12/4,3c | 4,3 | 7,7 | 1450 | 12,0 | 9,8 | 2,2 | 353 | 173 |  |

| 27 | E 12/4,3 | 4,3 | 7,7 | 1800 | 12,0 | 9,8 | 2,2 | 398 | 218 |  |

| 28 | E 12/6c | 6,0 | 10,8 | 1450 | 12,0 | 9,8 | 2,2 | 353 | 173 |  |

| 29 | E 12/6 | 6,0 | 10,8 | 1800 | 12,0 | 9,8 | 2,2 | 398 | 218 |  |

| 30 | E 12/10 | 10,0 | 18,0 | 2000 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 31 | E 12/12 | 12,0 | 21,6 | 2050 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 32 | E 12/15c | 15,0 | 27,0 | 2250 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 33 | E 12/20 | 20,0 | 36,0 | 2306 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 34 | E 13,5/2,5 | 2,5 | 4,5 | 1650 | 13,5 | 11,3 | 2,2 | 375 | 173 |  |

| 35 | E 13,5/4,3c | 4,3 | 7,7 | 1700 | 13,5 | 11,1 | 2,4 | 375 | 173 |  |

| 36 | E 13,5/4,3 | 4,3 | 7,7 | 2050 | 13,5 | 11,1 | 2,4 | 420 | 218 |  |

| 37 | E 13,5/6 | 6,0 | 10,8 | 2050 | 13,5 | 11,0 | 2,5 | 420 | 218 |  |

| 38 | E 13,5/10 | 10,0 | 18,0 | 2500 | 13,5 | 10,8 | 2,7 | 420 | 218 |  |

| 39 | E 13,5/12 | 12,0 | 21,6 | 2500 | 13,5 | 10,8 | 2,7 | 420 | 218 |  |

| 40 | E 13,5/15 | 15,0 | 27,0 | 2500 | 13,5 | 10,8 | 2,7 | 420 | 218 |  |

| 41 | E 15/2,5 | 2,5 | 4,5 | 1690 | 15,0 | 12,5 | 2,5 | 398 | 173 |  |

| 42 | E 15/4,3c | 4,3 | 7,7 | 1913 | 15,0 | 12,3 | 2,7 | 398 | 173 |  |

| 43 | E 15/4,3 | 4,3 | 7,7 | 2500 | 15,0 | 12,3 | 2,7 | 443 | 218 |  |

| 44 | E 15/6 | 6,0 | 10,8 | 2500 | 15,0 | 12,2 | 2,8 | 443 | 218 |  |

| 45 | E 15/10 | 10,0 | 18,0 | 2900 | 15,0 | 12,0 | 3,0 | 443 | 218 |  |

| 46 | E 15/12 | 12,0 | 21,6 | 3000 | 15,0 | 12,0 | 3,0 | 443 | 218 |  |

| 47 | E 15/15 | 15,0 | 27,0 | 3000 | 15,0 | 12,0 | 3,0 | 443 | 218 |  |

| Technical parameters of the concrete pole type EM | ||||||||||

| Lp. | Concrete pole type |

Strength [kN] |

Rupture force [kg] |

Weight [kg] |

Dimensions | Strength colour indication |

||||

| [m] | [mm] | |||||||||

| L | L1 | L2 | dp | dw | ||||||

| 1 | EM 10,5/15 | 15,0 | 27,0 | 1875 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 2 | EM 10,5/17,5 | 17,5 | 31,5 | 1907 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 3 | EM 10,5/20 | 20,0 | 36,0 | 1991 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 4 | EM 10,5/25 | 25,0 | 45,0 | 2082 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 5 | EM 12/15 | 15,0 | 27,0 | 2225 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 6 | EM 12/17,5 | 17,5 | 31,5 | 2383 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 7 | EM 12/20 | 20,0 | 36,0 | 2492 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 8 | EM 12/25 | 25,0 | 45,0 | 2518 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 9 | EM 13,5/15 | 15,0 | 27,0 | 2841 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 10 | EM 13,5/17,5 | 17,5 | 31,5 | 2893 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 11 | EM 13,5/20 | 20,0 | 36,0 | 3042 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 12 | EM 13,5/25 | 25,0 | 45,0 | 3086 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 13 | EM 15/15 | 15,0 | 27,0 | 3131 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

| 14 | EM 15/17,5 | 17,5 | 31,5 | 3131 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

| 15 | EM 15/20 | 20,0 | 36,0 | 3225 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

| 16 | EM 15/25 | 25,0 | 45,0 | 3225 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

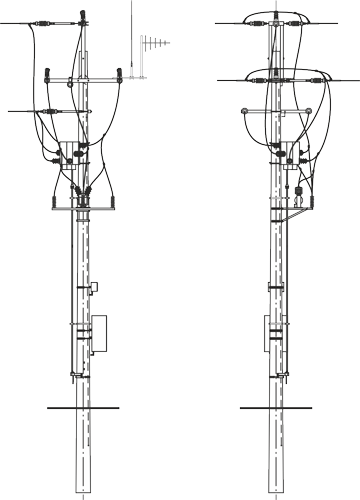

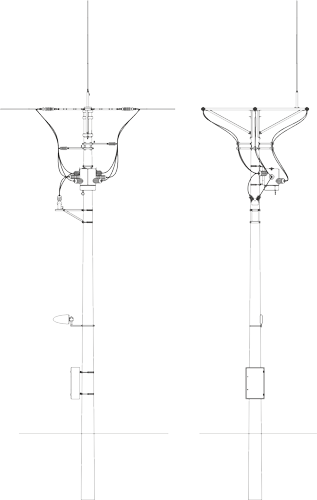

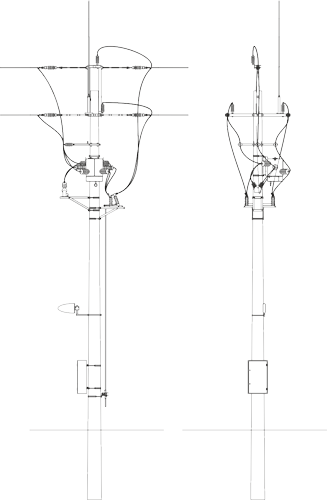

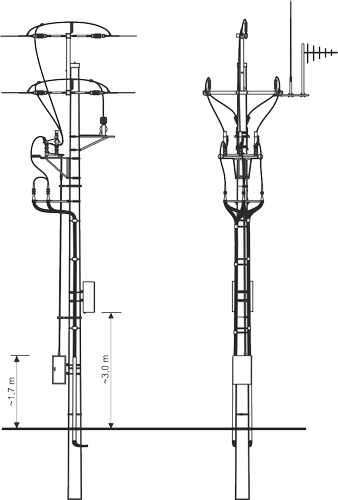

Concrete poles type E and EM

Technical parameters of the concrete pole type EU and EMU

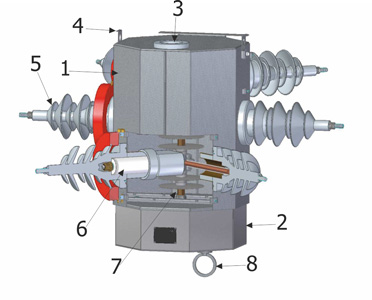

Legenda:

L - overall length of the concrete pole

dw - outside diameter of the apex

dp - outside diameter of the base

Concrete pole designation

| Technical parameters of the concrete pole type EU |

||||||||||

| Lp. | Concrete pole type |

Strength [kN] |

Rupture force [kg] |

Weight [kg] |

Dimensions | Strength colour indication |

||||

| [m] | [mm] | |||||||||

| L | L1 | L2 | dp | dw | ||||||

| 1 | EU 6,7/12 | 12 | 21,6 | 910 | 6,7 | 6,7 | 1,5 | 353 | 218 |  |

| 2 | EU 7,5/12 | 12 | 21,6 | 1055 | 7,5 | 6,7 | 1,5 | 330 | 218 |  |

| 3 | EU 8,2/4,3 | 4,3 | 7,7 | 990 | 8,2 | 6,7 | 1,5 | 353 | 218 |  |

| 4 | EU 8,2/6 | 6,0 | 10,8 | 990 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 5 | EU 8,2/10 | 10,0 | 18,0 | 1100 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 6 | EU 8,2/12 | 12,0 | 21,6 | 1150 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 7 | EU 8,2/15 | 15,0 | 27,0 | 1150 | 8,2 | 6,6 | 1,6 | 341 | 218 |  |

| 8 | EU 9/2,5 | 2,5 | 4,5 | 775 | 9,0 | 7,4 | 1,6 | 308 | 173 |  |

| 9 | EU 9/4,3 | 4,3 | 7,7 | 845 | 9,0 | 7,4 | 1,6 | 308 | 173 |  |

| 10 | EU 9/6c | 6,0 | 10,8 | 1250 | 9,0 | 7,4 | 1,6 | 308 | 173 |  |

| 11 | EU 9/6 | 6,0 | 10,8 | 1250 | 9,0 | 7,7 | 1,6 | 353 | 218 |  |

| 12 | EU 9/10 | 10,0 | 18,0 | 1300 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 13 | EU 9/12 | 12,0 | 21,6 | 1300 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 14 | EU 9/15 | 15,0 | 27,0 | 1380 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 15 | EU 9/20 | 20,0 | 36,0 | 1508 | 9,0 | 7,2 | 1,8 | 353 | 218 |  |

| 16 | EU 10,5/2,5 | 2,5 | 4,5 | 1100 | 10,5 | 8,7 | 1,8 | 330 | 173 |  |

| 17 | EU 10,5/4,3c | 4,3 | 7,7 | 1100 | 10,5 | 8,5 | 2,0 | 330 | 173 |  |

| 18 | EU 10,5/4,3 | 4,3 | 7,7 | 1500 | 10,5 | 8,5 | 2,0 | 375 | 218 |  |

| 19 | EU 10,5/6c | 6,0 | 10,8 | 1100 | 10,5 | 8,5 | 2,0 | 330 | 173 |  |

| 20 | EU 10,5/6 | 6,0 | 10,8 | 1500 | 10,5 | 8,5 | 2,0 | 375 | 218 |  |

| 21 | EU 10,5/10 | 10,0 | 18,0 | 1600 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 22 | EU 10,5/12 | 12,0 | 21,6 | 1650 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 23 | EU 10,5/15 | 15,0 | 27,0 | 1725 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 24 | EU 10,5/20 | 20,0 | 36,0 | 1878 | 10,5 | 8,3 | 2,2 | 375 | 218 |  |

| 25 | EU 12/2,5 | 2,5 | 4,5 | 1400 | 12,0 | 10,0 | 2,0 | 353 | 173 |  |

| 26 | EU 12/4,3c | 4,3 | 7,7 | 1450 | 12,0 | 9,8 | 2,2 | 353 | 173 |  |

| 27 | EU 12/4,3 | 4,3 | 7,7 | 1800 | 12,0 | 9,8 | 2,2 | 398 | 218 |  |

| 28 | EU 12/6c | 6,0 | 10,8 | 1450 | 12,0 | 9,8 | 2,2 | 353 | 173 |  |

| 29 | EU 12/6 | 6,0 | 10,8 | 1800 | 12,0 | 9,8 | 2,2 | 398 | 218 |  |

| 30 | EU 12/10 | 10,0 | 18,0 | 2000 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 31 | EU 12/12 | 12,0 | 21,6 | 2050 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 32 | EU 12/15c | 15,0 | 27,0 | 2250 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 33 | EU 12/20 | 20,0 | 36,0 | 2306 | 12,0 | 9,5 | 2,5 | 398 | 218 |  |

| 34 | EU 13,5/2,5 | 2,5 | 4,5 | 1650 | 13,5 | 11,3 | 2,2 | 375 | 173 |  |

| 35 | EU 13,5/4,3c | 4,3 | 7,7 | 1700 | 13,5 | 11,1 | 2,4 | 375 | 173 |  |

| 36 | EU 13,5/4,3 | 4,3 | 7,7 | 2050 | 13,5 | 11,1 | 2,4 | 420 | 218 |  |

| 37 | EU 13,5/6 | 6,0 | 10,8 | 2050 | 13,5 | 11,0 | 2,5 | 420 | 218 |  |

| 38 | EU 13,5/10 | 10,0 | 18,0 | 2500 | 13,5 | 10,8 | 2,7 | 420 | 218 |  |

| 39 | EU 13,5/12 | 12,0 | 21,6 | 2500 | 13,5 | 10,8 | 2,7 | 420 | 218 |  |

| 40 | EU 13,5/15 | 13,5 | 27,0 | 2500 | 13,5 | 10,8 | 2,7 | 420 | 218 |  |

| 41 | EU 15/2,5 | 2,5 | 4,5 | 1690 | 15,0 | 12,5 | 2,5 | 398 | 173 |  |

| 42 | EU 15/4,3c | 4,3 | 7,7 | 2500 | 15,0 | 12,3 | 2,7 | 398 | 173 |  |

| 43 | EU 15/4,3 | 4,3 | 7,7 | 2500 | 15,0 | 12,3 | 2,7 | 443 | 218 |  |

| 44 | EU 15/6 | 6,0 | 10,8 | 2500 | 15,0 | 12,2 | 2,8 | 443 | 218 |  |

| 45 | EU 15/10 | 10,0 | 18,0 | 2900 | 15,0 | 12,0 | 3,0 | 443 | 218 |  |

| 46 | EU 15/12 | 12,0 | 21,6 | 3000 | 15,0 | 12,0 | 3,0 | 443 | 218 |  |

| 47 | EU 15/15 | 15,0 | 27,0 | 3000 | 15,0 | 12,0 | 3,0 | 443 | 218 |  |

| Technical parameters of the concrete pole type EMU | ||||||||||

| Lp. | Concrete pole type |

Strength [kN] |

Rupture force [kg] |

Weight [kg] |

Dimensions | Strength colour indication |

||||

| [m] | [mm] | |||||||||

| L | L1 | L2 | dp | dw | ||||||

| 1 | EMU 10,5/15 | 15,0 | 27,0 | 1875 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 2 | EMU 10,5/17,5 | 17,5 | 31,5 | 1907 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 3 | EMU 10,5/20 | 20,0 | 36,0 | 1991 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 4 | EMU 10,5/25 | 25,0 | 45,0 | 2082 | 10,5 | 8,3 | 2,2 | 420 | 263 |  |

| 5 | EMU 12/15 | 15,0 | 27,0 | 2225 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 6 | EMU 12/17,5 | 17,5 | 31,5 | 2383 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 7 | EMU 12/20 | 20,0 | 36,0 | 2492 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 8 | EMU 12/25 | 25,0 | 45,0 | 2518 | 12,0 | 9,5 | 2,5 | 443 | 263 |  |

| 9 | EMU 13,5/15 | 15,0 | 27,0 | 2841 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 10 | EMU 13,5/17,5 | 17,5 | 31,5 | 2893 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 11 | EMU 13,5/20 | 20,0 | 36,0 | 3042 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 12 | EMU 13,5/25 | 25,0 | 45,0 | 3086 | 13,5 | 10,8 | 2,7 | 465 | 263 |  |

| 13 | EMU 15/15 | 15,0 | 27,0 | 3131 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

| 14 | EMU 15/17,5 | 17,5 | 31,5 | 3131 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

| 15 | EMU 15/20 | 20,0 | 36,0 | 3225 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

| 16 | EMU 15/25 | 25,0 | 45,0 | 3225 | 15,0 | 12,0 | 3,0 | 488 | 263 |  |

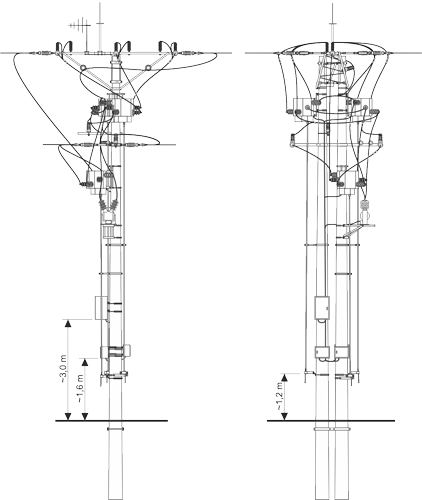

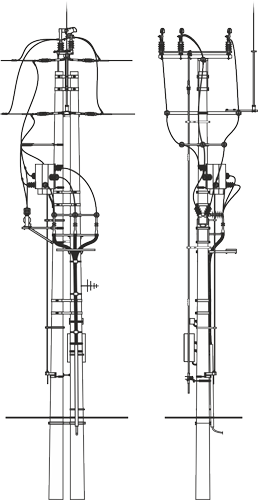

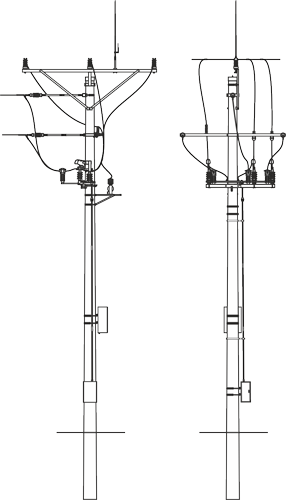

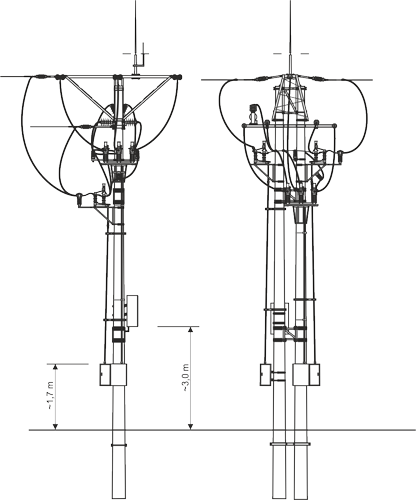

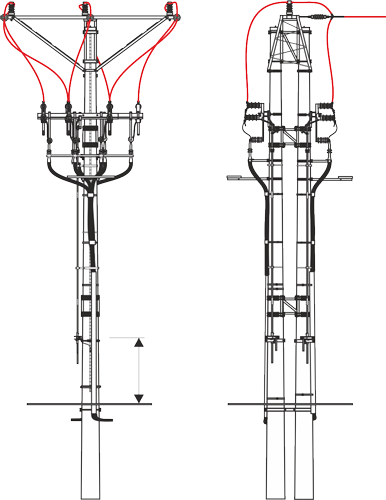

Concrete poles type EU and EMU

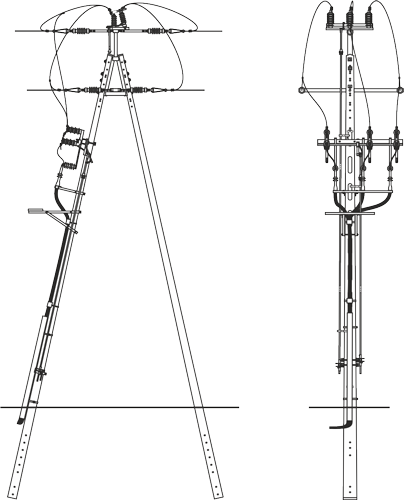

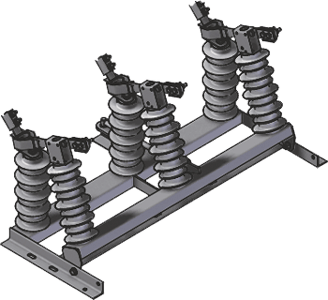

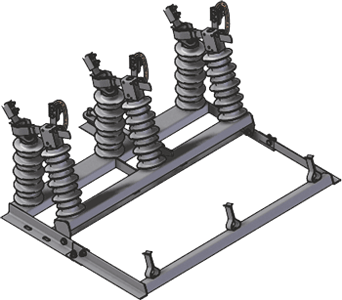

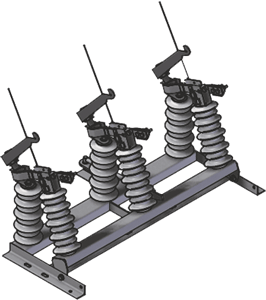

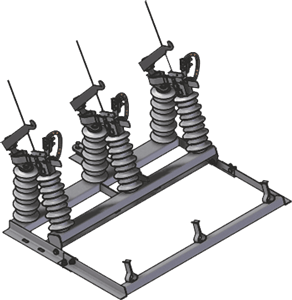

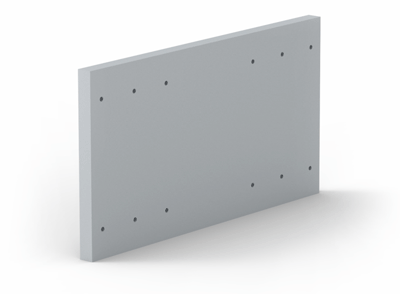

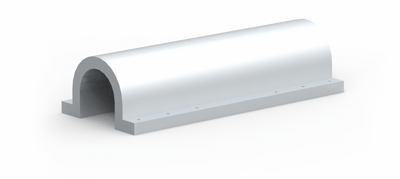

Prefabricated footing elements

Precast concrete is designed for concrete poles and transformer stations foundations in MV and LV overhead networks. Concrete prefabricated footing and fundament elements are made from concrete class C 30/35. Footing elements should be chosen based on PTPIREE albums and assessment of the ground parameters according to the regulations defined in PN-81/B-03020 and PN-80/B-03322 norms.

| List of footings and fundaments | |||

| Lp. | Footing type | Type | Footing elements |

| 1. | Footing plates | UP 1 ÷ 7 | Plate U - 85 Plate U - 130 Alloyed plate 0,3 x 0,3 Bracket OU-1, OU-2, OU-6/VE |

| 2. | Footing plates | UP 11 ÷ 18 | Plate U - 85 Plate U - 130 Element ES-2 Alloyed plate 0,3 x 0,3 |

| 3. | Footing blocks | To the concrete pole ŻN i BSW |

Block B - 60 Block B - 80 Block B - 90 Block B - 150 |

| 4. | Prefabricated fundaments |

SFP 111, 122, 133 SFP 21/L, 22/L, 23/L SP 1, 2, 3 SP 11, 22, 33 |

Bottom plate PD Plate PS 120 Plate PS 160 Plate PS 200 Screw connections SFP 2 /L |

| 5. | Prefabricated fundaments |

FP 11, 12, 13 FP 21, 22, 23 |

Element EF Plate P - 120 Plate P - 160 Plate P - 200 Assembly bolts |

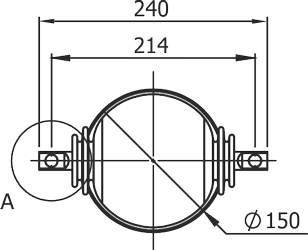

| Table footing elements |

|||

| Element name |

Symbol of the element |

a [cm] |

Element weight |

| Footing plate |

P - 120 | 120 | 675 kg |

| P - 160 | 160 | 900 kg | |

| P - 200 | 200 | 1125 kg | |

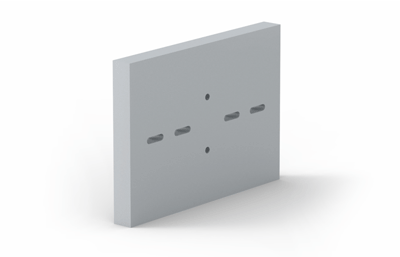

| Element sketch | |||

|

|||

| Symbol of the element |

a [cm] |

Element weight |

|

| PS - 120 | 120 | 400 kg | |

| PS - 160 | 160 | 530 kg | |

| PS - 200 | 200 | 660 kg | |

| Element sketch | |||

|

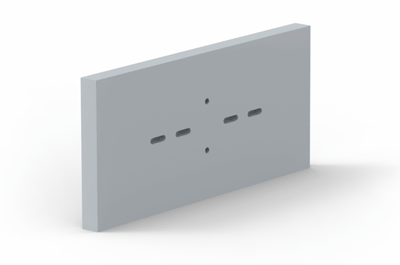

|||

| Symbol of the element |

Element weight |

||

| U - 85 | 77 kg | ||

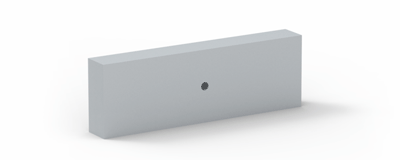

| Element sketch | |||

|

|||

| Symbol of the element |

Element weight |

||

| U - 130 | 156 kg | ||

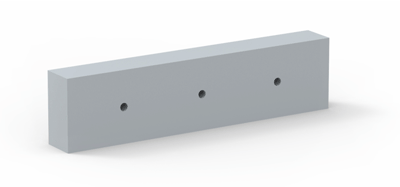

| Element sketch | |||

|

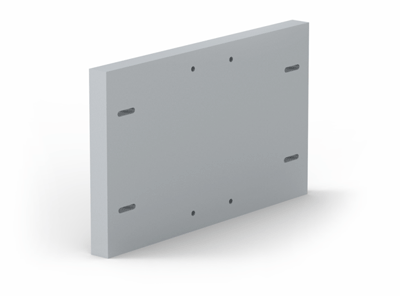

|||

| Symbol of the element |

Element weight |

||

| Bottom plate PD | 510 kg | ||

| Element sketch | |||

|

|||

| Element name |

Symbol of the element |

Element weight |

|

| Footing blocks |

B - 60 | 23 kg | |

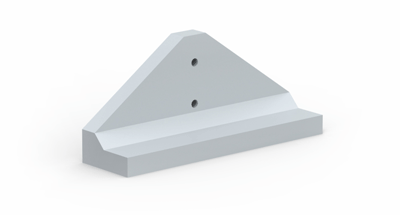

| Element sketch | |||

|

|||

| Symbol of the element |

Element weight |

||

| B - 80 | 38 kg | ||

| Element sketch | |||

|

|||

| Symbol of the element |

Element weight |

||

| B - 90 | 72 kg | ||

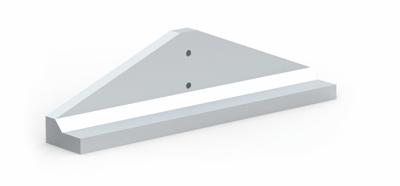

| Element sketch | |||

|

|||

| Symbol of the element |

Element weight |

||

| B - 150 | 120 kg | ||

| Element sketch | |||

|

|||

| Element name |

Symbol of the element |

Element weight |

|

| Footing elements |

EF | 1060 kg | |

|

|||