SPS (Smart Power Station)

Smart energy management system – SMART GRID

Concrete container transformer stations with inside working corridor

Transformer substations in concrete enclosures with external servicing

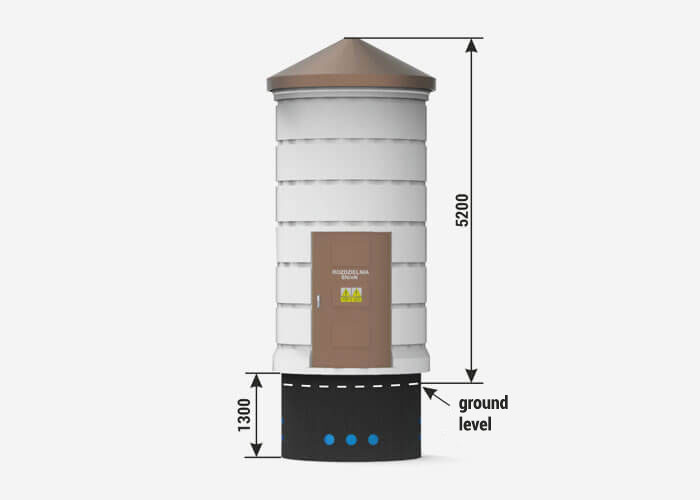

WST - Advertising pole

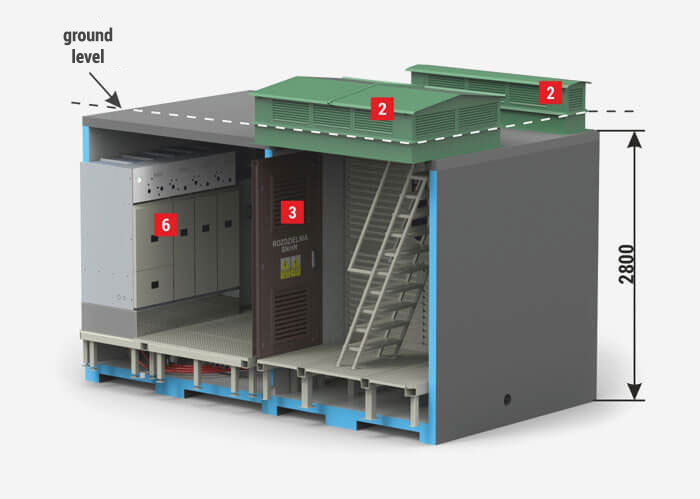

PST-b - Underground transformer substation

MRw-bS type substations in concrete enclosure

ZK-SN MV connection box in concrete enclosure

Substations with generator units

Dedicated substations for renewable energy sources

Reactive power compensation substation

Solutions for main power supply stations

Stations dedicated to the needs of the railway industry

Transformer substations in metal enclosures

Medium-Voltage/Low-Voltage Substations

A MV/LV power substation is an electrical substation where a change in the parameters of electric current takes place. This is done at different voltage levels. The most common are substations that are used to transform (change) medium voltage (e.g. 20 kV, 15 kV) to low voltage (400 V).

The second task of MV/LV transformer substations is to distribute electricity, which then goes to the end-user. A distribution substation is usually built as the last element in the path of energy supply to the customer. Such a device can be supplied from a cable or overhead line.

A MV/LV substation includes:

- A transformer,

- A medium-voltage switchgear,

- A low-voltage switchgear,

- Auxiliary elements of the structure.

The transformer changes the voltage of an electric current from higher to lower or from lower to higher. The transfer of AC energy is carried out by induction from one electrical circuit to another, while maintaining the original frequency. Although usually the electrical voltage is then changed by the transformer, an isolation transformer is an exception to this rule. The purpose of isolation transformers is to provide additional protection for the circuits being energized through galvanic separation.

Medium- and low-voltage switchgears, on the other hand, makes it possible to safely connect, interrupt, or separate electrical circuits. By means of built-in electric power protection automatics and a remote supervision system, they protect the power grid and enable its rapid reconfiguration, guaranteeing continuity in the supply of electricity.

Types of transformer substations

Due to the location and method of placement, we distinguish the following types of substations:

- Pole-mounted transformer substations (overhead)

- Indoor transformer substations,

- Containerized transformer substations (small-size, urban),

- Mobile transformer substations (transportable).

Prefabricated transformer substations

Compact substations are made in the form of a ready-made enclosure equipped with all the basic electrical equipment: transformers, MV switchgear, LV switchgear, internal installations. Such substations differ in terms of dimensions, types of housing (e.g. concrete housing, metal housing), and interior equipment. In addition, they can have external or internal service.

ZPUE substations

ZPUE S.A. has been manufacturing transformer substations for over 30 years. Experience backed by highly specialized engineering knowledge has allowed the company to create a wide range of solutions aimed at professional power, industry, renewable energy sources, as well as specialized solutions dedicated to rail transportation. The production of nearly 3,000 thousand stations per year gives ZPUE S.A. a leading position in this field in the European market. Moreover, over the years, the company has also become a well-known and trusted supply partner on the European and global markets.

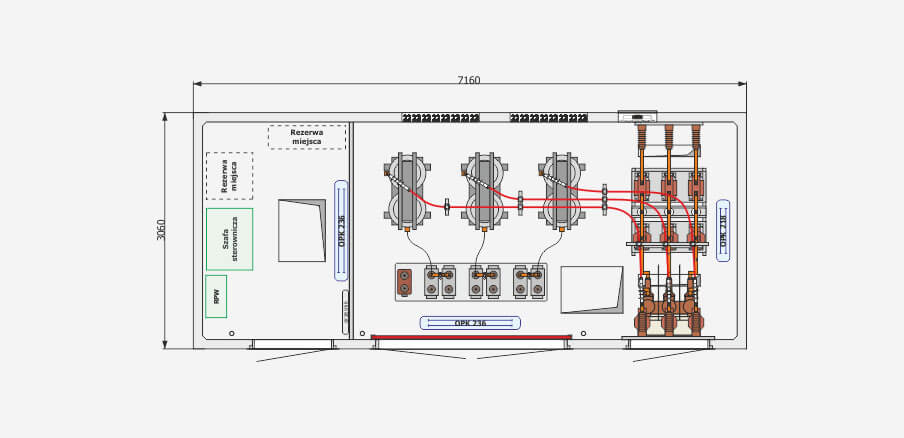

Substations in concrete enclosures with an internal service corridor of the MRw-b type are prefabricated containerized substations consisting of three monolithic reinforced concrete elements made in C30/37 class: the foundation, the main body, and the roof. In the standard design, the station structure allows the insertion of encapsulated transformers with a power of up to 1000 kVA. We also offer solutions that allow the installation of units of higher power (up to 4 MVA) in various designs (oil with conservator, resin, specialized). Installation of the transformer is carried out through the door of the transformer chamber or from above after removing the roof, while its operation is carried out after opening the door to the transformer chamber.

Depending on the purpose, switchgears of our own manufacture are installed in the stations:

- SN – primary energy distribution: RELF, RELF 2S, RXD;

- SN – secondary energy distribution: Rotoblok, Rotoblok SF, Rotoblok VCB GIS, TPM;

- nN – RN-W, Instal-Blok, ZR-W, Sivacon;

- Others – by agreement with the manufacturer.

The above-mentioned switchgears are independent, insertable elements of station equipment, and their operation is carried out - depending on the variant of the station itself - from the inner corridor or from the outside after opening the door of a particular compartment. Connections between MV switchgear and transformer and between transformer and LV switchgear are made by cables or, optionally in special designs, by rail bridges or busways.

A transformer substation with integrated energy storage

The increase in demand for electricity in the world is growing, accumulating at certain times of the day and year. Meeting increasing energy needs involves expanding power plant capacity and transmission lines. While this leads to meeting the needs of the consumer (industrial and private), at the same time it inevitably results in the appearance of surplus power at the supplier during the night time (valley and peak energy). Similar problems are caused by an oversupply of energy generated by renewable energy source (wind and photovoltaic) power plants. The development of the electric car market creates another component of the power market, which will not be followed by the process of expanding generation infrastructure. However, balancing the power system can be carried out by investing in energy storage.

We believe that the answer to the problems aforementioned is the SPS (Smart Power Station). The main task of the device is to connect consumers to the power system through energy storage. Smart Power Station combines the functionality of a distribution substation with energy storage, RES sources, and an electric vehicle charger, managed by a single SCADA system. This innovative solution is protected by a patent application, utility model and industrial design.

This substation with integrated energy storage system was designed, manufactured, and commissioned from scratch by our engineers. The modular design allows the investor to scale the storage from a dozen kWh to several tens of MWh, also allowing control of the return to the grid or for own use (powering house, charging vehicles).

Individual approach and flexibility

Thanks to many years of experience and a team of qualified engineers, we are able to prepare solutions tailored individually to the needs of even the most demanding customers. This is evidenced by deliveries to such contractors as Innogy, ČEZ, EON, RWE, Alstom, and many others.